Formula Student EAST - Data logger

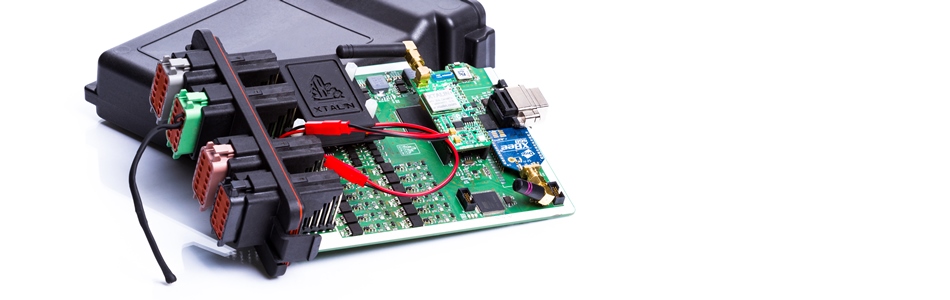

Formula Student competitions are made to improve practical and intellectual skills of university students in a real-life, competitive environment. Most Xtalin employees take part in organization of Formula Student East event every year. There are three categories in the event: Combustion, Electric and Driverless racecars (the last can be both propelled with a combustion engine or electric motors). For the event in 2018, Xtalin developed a Data Logging system for FS East to monitor the energy consumption for the electric vehicles, and the autonomous system of driverless vehicles. Also it records if any of the measured signal exceeds the limits defined by the Formula Student Rules.

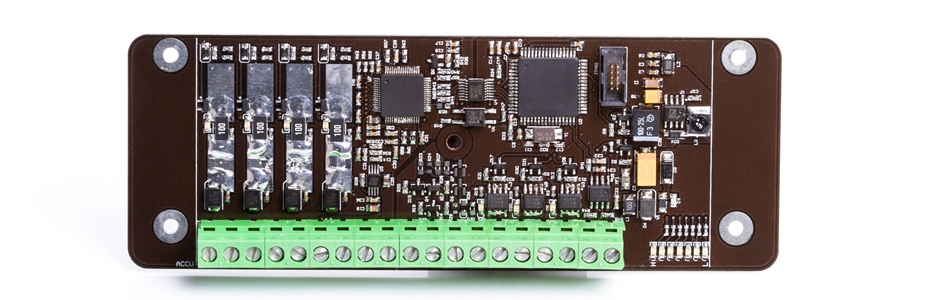

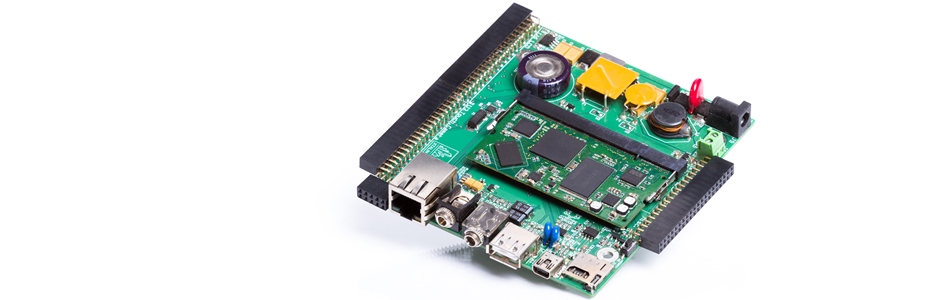

The main goal was to create an easy to fit, easy to use and easy to check system. Organizers and scrutineers have to configure the data logger and download the recorded information. These are done through an intuitive graphical user interface (GUI). You can connect to the device via a password protected wireless data channel. To download any records, you need administrative privilege credentials. Therefore, the teams are not able to access/abuse the confidential files. There is an interface to analyse and check all the measurements whether they are complying with the strict rules and draws the recorded signals in an illustrative diagram.

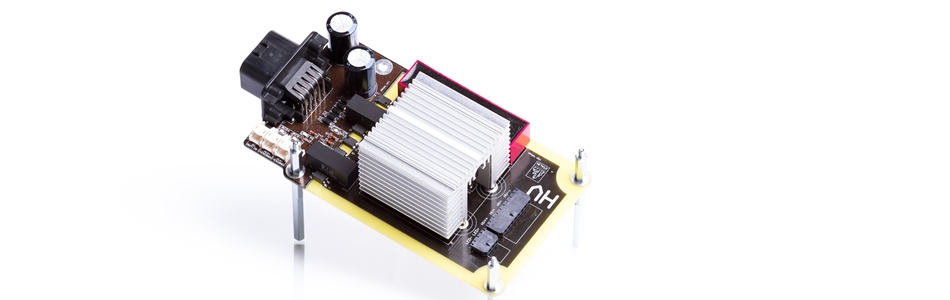

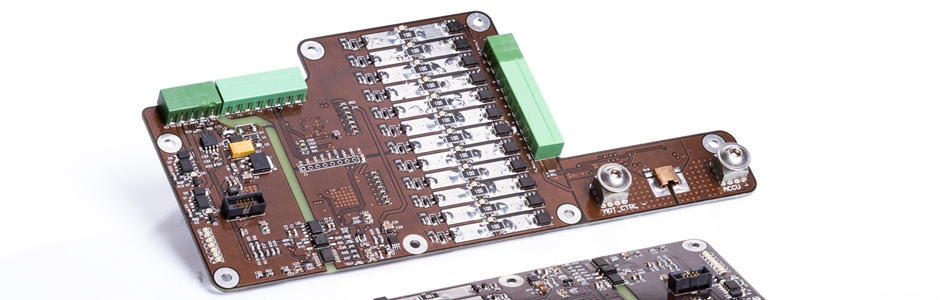

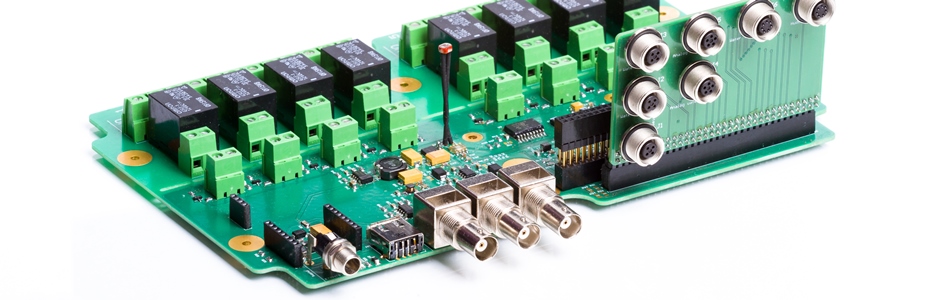

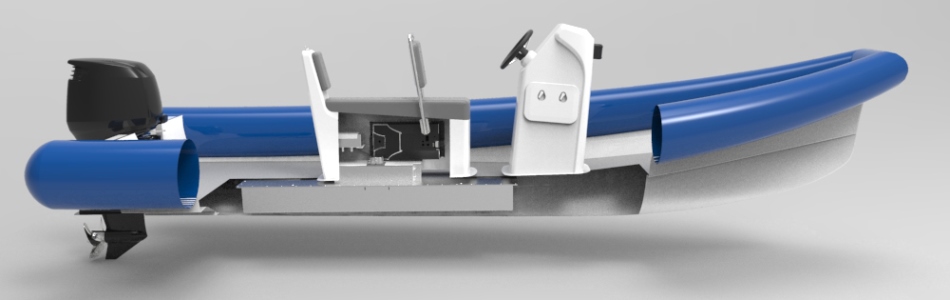

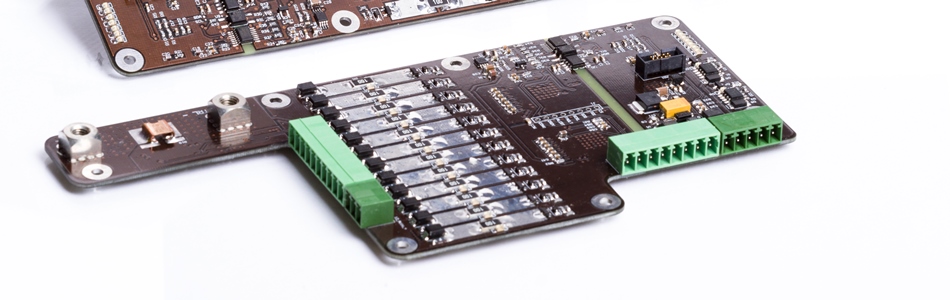

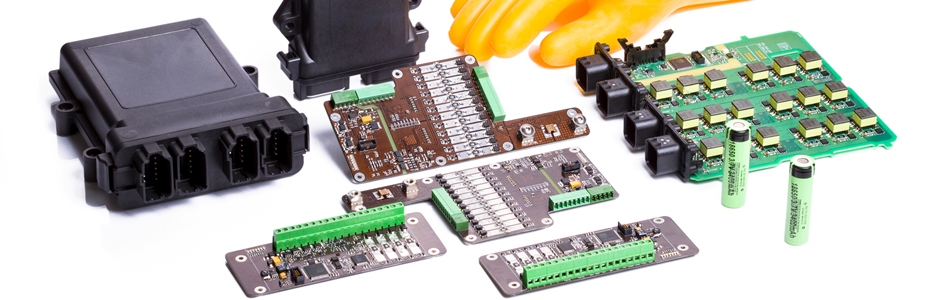

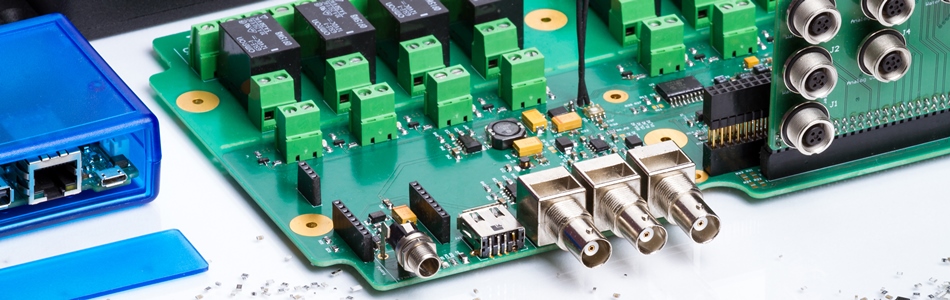

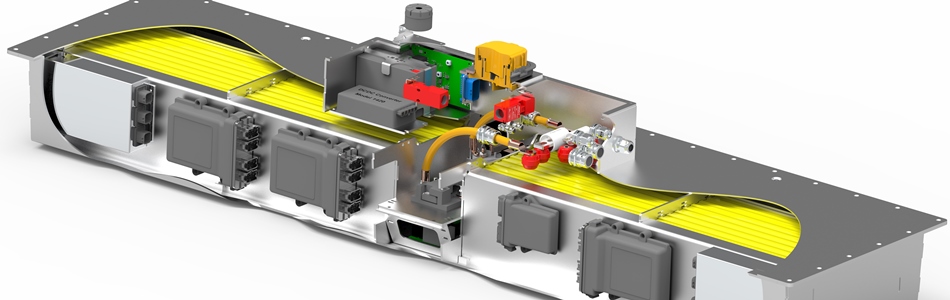

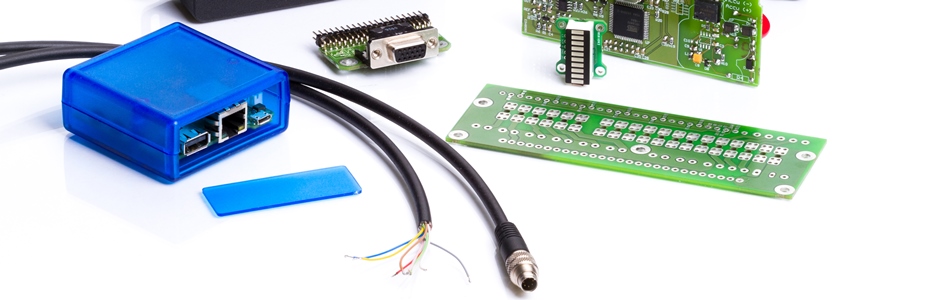

As the teams must mount this device in their vehicle, it must be as small as possible. The racecars must be water resistant, therefore this electronic device is also made this way with IP68 protection. As some of the driverless cars have combustion engine, and measuring the electric energy consumption is pointless, the energy measurement sensor is separated from the logger. The device connects to the vehicle’s data communication line via highspeed CAN-bus, and the sensor is also connected to the data logger the same way. The data logger can be placed nearly anywhere in the vehicle, as it uses wireless communication to download data.

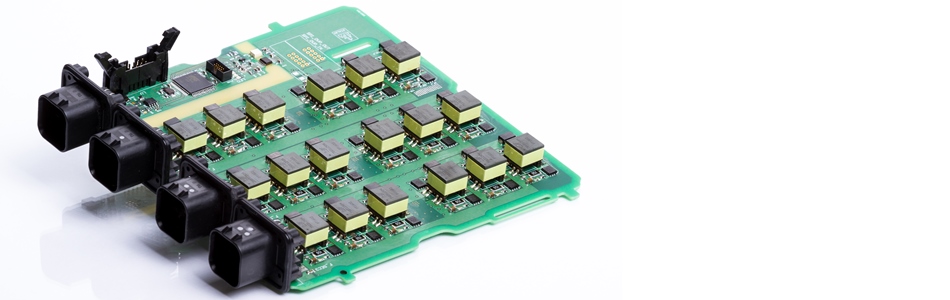

The electric drivetrain consumption is monitored by a high precision sensor capable of measuring 0-600V and -500 – 500A with 10mV and 10mA accuracy. Energy is calculated separately for both directions, so the efficiency of recuperation can be taken into account with a factor described by the Rules. The software automatically detects if the sensor is connected to the tractive system with inverted polarity and calculates with the right values.

During the FS East event in 2018, all data logger and energy meter devices worked without a failure, due to our preliminary electric, system and field tests. Log files could be downloaded wirelessly for all teams in a short time, which made the participant's job easier.